A Beginner’s Guide to Top Drive Rigs: What You Need to Know

Top drive rigs have transformed the oil and gas industry, making drilling operations safer, faster, and more efficient. If you’re new to the concept, don’t worry—this guide will break it down for you in simple terms. By the end, you’ll understand what top drive rigs are, how they work, and why they’re so important.

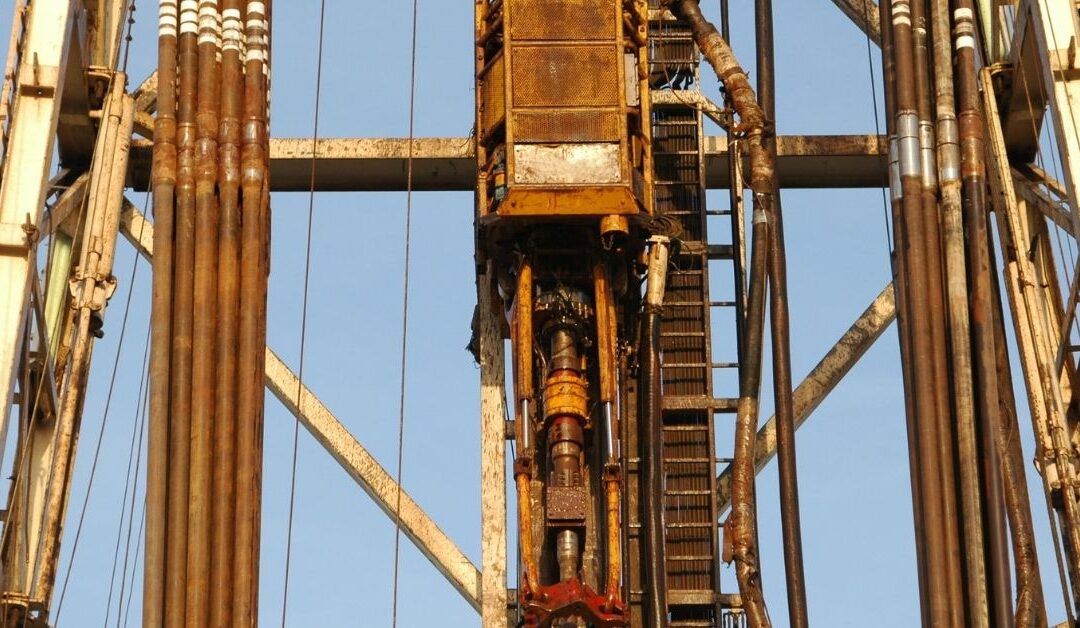

What is a Top Drive Rig?

A top drive rig is a piece of equipment used in drilling operations to rotate the drill string (the long pipe that drills into the ground). Unlike older systems that rotate the pipe from the bottom, a top drive rig does this from the top. This design not only speeds up the process but also makes it safer and more efficient.

Think of it as upgrading from a manual screwdriver to a power drill—it’s faster, easier, and gets the job done with less effort.

How Does a Top Drive Rig Work?

Here’s how it works: the top drive rig is mounted on the derrick (the tall structure on a drilling rig). It suspends the drill string and uses a motorized system to rotate it. The top drive moves up and down the derrick, allowing for continuous drilling without stopping to add new sections of pipe manually.

This continuous operation saves time and reduces the risk of errors, making it a favorite in modern drilling projects.

What Are the Different Types of Top Drive Rigs?

Top drive rigs come in three main types, each designed for specific needs:

1. Electric Top Drive Rigs

These rigs use electric motors to rotate the drill string. They’re known for their precision and are often used in projects that require a high level of control.

2. Hydraulic Top Drive Rigs

Hydraulic rigs rely on hydraulic systems to generate the torque needed for drilling. They’re a great choice for locations where electric power isn’t easily available.

3. Mechanical Top Drive Rigs

Mechanical rigs use gears and chains to rotate the drill string. They’re tough, reliable, and perfect for heavy-duty drilling operations.

What Are the Advantages of Using a Top Drive Rig?

Top drive rigs offer several benefits that make them a go-to choice in the oil and gas industry:

1. Increased Efficiency

Top drive rigs allow for continuous drilling, which means less downtime and faster project completion. This efficiency can save both time and money.

2. Reduced Risk of Accidents

By automating many parts of the drilling process, top drive rigs reduce the need for manual labor, lowering the risk of accidents and injuries.

3. Improved Drilling Performance

Top drive rigs provide better control, which is especially useful in complex drilling scenarios like directional or horizontal drilling.

What Are the Limitations of Using a Top Drive Rig?

While top drive rigs are impressive, they’re not without their challenges:

1. Higher Initial Cost

Top drive rigs are more expensive to buy and install compared to traditional systems.

2. Requires Skilled Operators

Operating a top drive rig isn’t something just anyone can do—it requires specialized training, which can add to labor costs.

3. Limited in Certain Environments

Some extreme environments or unique geological conditions may not be ideal for top drive rigs.

What Are the Applications of Top Drive Rigs?

Top drive rigs are incredibly versatile and can be used in a variety of drilling operations:

1. Onshore Drilling

They’re commonly used in onshore projects, where their efficiency and safety features shine.

2. Offshore Drilling

In offshore environments, top drive rigs handle the challenges of deepwater drilling, such as high pressures and harsh conditions.

3. Directional Drilling

Top drive rigs are perfect for directional drilling, where precision is key to reaching target reservoirs.

What Are the Safety Measures to Consider When Using a Top Drive Rig?

Safety is always a priority in drilling operations. Here are some key measures to keep in mind:

1. Proper Training and Certification

Make sure all operators and crew members are trained and certified to handle top drive rigs.

2. Regular Maintenance and Inspections

Routine maintenance and inspections can catch potential issues before they become major problems.

3. Following Safety Protocols

Always stick to established safety guidelines to minimize risks and ensure a safe working environment.

How to Choose the Right Top Drive Rig for Your Project?

Choosing the right top drive rig depends on your project’s specific needs. Consider factors like the type of drilling operation, your budget, and the environmental conditions. Consulting with experts or companies like Norton Energy Drilling, which specializes in customized solutions, can help you make the best choice.

FAQ Section

What are the main components of a top drive system, and how does each contribute to the drilling process?

The main components of a top drive system include:

- Motor: Powers the rotation of the drill string.

- Swivel: Allows drilling fluid to circulate through the drill string.

- Torque System: Provides precise control during drilling.

Together, these components ensure efficient and safe drilling operations.

What are the advantages and disadvantages of using a top drive system compared to a rotary table system?

Top drive systems are faster, safer, and more efficient than rotary table systems. However, they’re more expensive and require skilled operators, which can be a drawback for some companies.

In what types of drilling operations (e.g., deepwater, directional) are top drive systems most commonly used, and why?

Top drive systems are widely used in deepwater, offshore, and directional drilling. Their ability to provide precise control and handle complex scenarios makes them ideal for these applications.

To stay updated on the latest advancements and insights in the oil and gas industry, follow the latest Oil and Gas Industry News on Energy Workforce.

Conclusion

Top drive rigs are a vital tool in modern drilling operations. They offer unmatched efficiency, safety, and versatility, making them a preferred choice for onshore, offshore, and directional drilling projects. By understanding the basics, you’ll be better equipped to make informed decisions and optimize your operations.

Recent Comments